SeLected PROJECTS

Nanue Stream Bridge

We are rebuilding what was originally a railroad bridge on the Big Island of Hawaii with modern steel while maintaining the historic 1912 aesthetic for passenger vehicle and heavy truck travel.

I-205 Abernethy Bridge

These steel support structures and barriers support safe construction on the I-205 Abernethy Bridge, and aluminum bubble rings protect fish and wildlife during construction.

Woodfibre Pile Drilling Platform

This steel marine structure weighing approximately 1 million pounds will be used to drill the foundation pilings for the LNG terminal in remote British Columbia.

East County Library

These custom steel connections support huge mass timber beams for the 95,000 square foot East County Library. This beautiful new landmark is now also more sustainable and earthquake resilient.

Thermalito Dam Radial Gates

These curved radial gates for the Thermalito hydropower dam are designed to be lightweight, which is both more economical and environmentally-friendly.

Ice Harbor Dam Bulkheads

These new bulkhead gates support the US Army Corps of Engineers' operation and maintenance of the Ice Harbor hydroelectric dam on the Snake River.

Woodfibre Breasting Dolphins

These marine structures will support a giant "floatel" to house work crews at a remote job site on the west coast of British Columbia supporting LNG as a more sustainable option to help North America transition to fully renewable energy.

Bonneville Dam Sluiceway Roller Gate

Thiscomplex wheeled lift gate allows the US Army Corps of Engineers to open and close the sluiceway on the Bonneville Dam and keep floating debris like tree branches from getting into the turbines.

Port of Portland Dredging Operations

Barge spuds for the Port of Portland allow dredging vessels to safely anchor, and custom dredging pipes help ensure the maintenance of the critical shipping channel from the Metro region to the Pacific Ocean.

Trinity Dam Spherical Bulkhead

This spherical bulkhead allows the Bureau of Reclamation to control the flow of water on the Trinity River in the Klamath River basin.

Moveable Shiploader Truss Bridge

This large movable truss bridge will be used to unload bulk cargo such as gravel and grain from large ships.

Nickajack Dam Bulkhead Storage Racks

These bulkhead storage racks support the US Army Corps of Engineers' operation and maintenance of the Nickajack hydroelectric dam on the Tennessee River.

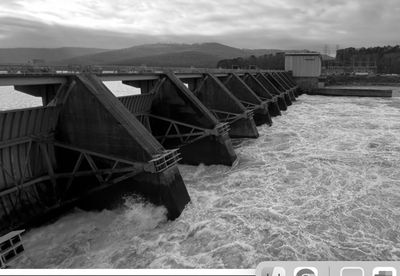

Cedar Rapids Roller Gate

This flood control gate helps the US Army Corps of Engineers to protect people from increasingly frequent flooding on the Cedar River.

McNary Dam Bulkheads

These 70 ton bulkhead gates allow the US Army Corps of Engineers to block water flow through any of the hydropower turbine generators on the McNary Dam on the Columbia River, which can then be dewatered to allow personnel to do maintenance work on the turbine.

Research & Development

Robotic Welding- Small Business Innovation Research Grant

WTF is conducting research supported with US Department of Energy SBIR grants to optimize the fabrication of the massive components needed for floating offshore wind platforms, wave energy devices, and pumped storage hydropower systems. The cutting-edge manufacturing techniques we are refining will improve the cost-competitiveness of scaling design, and significantly reduce fabrication timelines to help ensure that this critical infrastructure can be manufactured in the US.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.